CAPABILITIES

SL Industries Ltd. realizes that in the constant battle for higher-performing steel products, customers will impose a unique set of challenges, not the least of which is learning how to weld more, and faster and how to weld different materials, including high-strength steels that are being used ever more frequently.

SL Industries Ltd. is continuously investing in the training and certification of its employees, new robotic welding equipment, and precisely documenting the welding techniques and quality control procedures. The company employs more than 50 welding specialists certified to apply all major types of welding both, manual and robotic in order to guarantee the highest quality of the most complex customized components:

- We apply 100% third-party inspection of most critical welds using Magnetic Particle Inspection and Ultrasonic Flaw Detection techniques.

- Under evaluation are plans for the introduction of LASER BEAM or LASER-HYBRID welding techniques in the near future.

EXPERIENCE IN WELDING HIGH-STRENGTH STEELS

The demand for innovative stronger and lighter welded components by heavy equipment manufacturers is on the rise. Due to the elevated strength-to-weight ratio, high-strength steels are used to build products that carry more, weigh less, and withstand extreme service conditions.

Our team focused to master the welding of materials that meet these demands such as steels with yield strengths from 586 MPa (85 KSI) and up to 1200 MPa (160 KSI).

Documented Welding Processes

Based on ISO and AWS standards, SL Industries Ltd. has developed a company welding procedure (WPS) to provide direction for its welders to follow in order to produce high-quality and consistent welds that meet all codes and customer requirements. The company is investing in specialized software to keep track of welded products, welders’ qualifications, and code compliance.

OUR equipment

Advanced Machinery Portfolio

From Precision Laser Cutting & CNC Milling to Robotic Welding and Material Handling: Explore Our Diverse Equipment Lineup

| Laser, Plasma, and Oxy Fuel Cutting Machines | |

| LAZER 2016- LVD, IMPULS 12530 | table x-12,000 x y-3000, thickness up to 20mm |

| LASER CUTTING MACHINE – TRUMPF 3030 | Table 1500 х 3000 mm, thickness cut up to 18 mm |

| OXY FUEL CUTTING MACHINE – CNC ZINSER | table 12000 x 2500, thickness up to 30mm plasma; 350mm oxy fuel |

| (2017) CLOOS Robotic Plasma System for cut & bevel with QRC410 Robot, HiFocus 160i-Plasma and Moses BLECH controls | 13000 x 3000mm, thickness-0.5 to 30mm |

| PLASMA & GAS CUTTING MACHINE ZINSER PMAX 1650 (2015) | Table 12000 х 3160 mm, thickness up to 35mm (oxy fule-100mm) |

| Brake Presses | |

| HYDRAULIC BRAKE PRESS | 63t x 520mm |

| HYDRAULIC BRAKE PRESS DURMA (2006)- HAP30200 | 200t x 3000mm |

| Hydraulic Brake Press Durma (2014) AD-S TANDEM 600+400 TON L=12000mm | 600t x 12000mm |

| Welding Equipment | |

| WELDING STATION WITH FOUR TORCHES | Rotator 10000 x 2500 x 2000mm, up to 20,00kg capacity |

| ESAB CAB SYSTEM 600M FOR BOOMS WITH DUAL LAE1001SAW with 20-ton ROTATOR | 1000A * (2) |

| ESAB SUBARC TRACTOR- A2 Multitrac with A2-A6 Process Controller PEK | |

| Welding Robots (4 units) MOTOMAN-YASKAWA MRC | |

| WELDING ROBOT – FANUK/MECOME R-30iA with 12,000 mm, 20-ton rotator | Rotator 10000 x 2500 x 2000mm, up 20,00kg capacity |

| WELDING ROBOT ABB | Material Handling in Facilities |

| Cloos Robotic Welding System CS60 DH-TSC w/Robot QRC350-E, Welder QINEO PULSE, Positioner-DH-TSC-10t w/ 2 Loading Stations | PULSE 600A |

| TIG / MIG VARIOUS WELDING EQUIPMENT – LINCOLN / HOBART / MILLER / ESAB / KEMPY | 30 working stations |

| CNC Milling and Boring | |

| REIDEN LHBZ-3M-GA CNC 4-Axes Machining Center | x-travel 1400, y-vertical 1500, z-travel 1000mm, table D=1250 |

| CINCINNATI ARROW 750 VERTICAL Machining Center | Table 950х520 |

| ZAYER KM6000 Universal CNC Machining Center | x-travel 4300, y-vertical 1500, z-travel 1050mm, table 6000 x 1200 |

| MILLING MACHINE – HELLER W/TOOLCHANGER 24, ISO50 | x-travel 1800, y-travel 800, z-travel 710mm |

| DUAL SPINDLE Horizontal CNC – AXA HFB2 (2009) | x-travel 3500, y-vertical 700, z-travel 900mm |

| FERMAT Boring Machine Center WFT13, Tool Changer 64 (2017) | x-travel 4000, y-vertical 2000, z-travel 1500mm (+730mm) |

| CNC BORING CENTER – HMC200 with tool changer 48 tools | x-travel 3000, y-travel 1500, z-travel 1500mm, table 1200 x 1200 |

| UNIVERSAL MILLING MACHINE ANAYAK HVM 3300 | x-travel 2700, y-vertical 1030, z-travel 930mm |

| UNIVERSAL MILLING MACHINE COLGAR- PROGRAM 200, TOOL CHANGER 40, | x-travel 6000, y-vertical 1500, z-travel 1000mm |

| BORING – TOS VARNSDORF | x-travel 1250, y-travel 1250, z-travel 1250mm, rotating table |

| Large CNC Machine Centers | |

| CME Traveling Column CNC Machine Center – FCM10000, Tool Changer | x-travel 10000, y-vertical 3100, z-travel 1500mm, table 10000 x 3500 |

| SORALUCE FS8000 Traveling Column CNC Machining Center, Tool Changer | x-travel 8000, y-vertical 2000, z-travel 1500mm, table 10000 x 3500 |

| Lathes- Universal & CNC | |

| UNIVERSLA LATHE – POREBA TPK 80/2M | L=2200/ DIA 850 |

| UNIVERSLA LATHE – C500 | L=1500mm / ø500 |

| CNC LATHE CINCINNATI FALCONE 400 | dia 400, x-axes 300mm, z-axes 850mm |

| CNC LATHE MAGDEBURG S300 P12 | dia 580, x-axes 410mm, z-axes 915mm, 53kW |

| Universal Milling & Drilling Machines | |

| TWO COLUMN DRILLS PK-32 | DIA 20 |

| RADIAL DRILLING MACHINE – MAS VO50 | МАХ DIA 50 mm |

| MILLING MACHINE HECKERT | x-travel 840, y-travel 420, z-travel 400mm |

| UNIVERSAL MILLING MACHINE | x-travel 950, y-travel 350, z-travel 450mm |

| VERTICAL MILLING MACHINE | x-travel 1200, y-travel 350, z-travel 400mm |

| RADIAL DRILLING MACHINE – HMT | |

| Grinding & Other machines | |

| THREAD ROLLING MACHINE | up to 40mm |

| CENTERLESS GRINDING | DIA 10-150 mm |

| Cylindrical GRINDING MACHINE – BENDIX ACC 144A S/M | Ø101,6 mm (4”) L 800mm |

| Shotblasting & Painting Equipment | |

| SHOTBLASTING MACHINE – CLEMCO | |

| SHOTBLASTING BOOTH – VACUBLAST | 6000 x 4500 x 4000mm |

| PAINTING BOOTH for large parts & machines | 8000 х 4500 х 4500 mm |

| PAINT BOOTH with CURING OVEN | 25 000 х 4000 х 3000 mm |

| SANDBLASTING MACHINE CLEMKO 2452 | |

| Material Handling in facilities | |

| BRIDGE CRANE DEMAG / TEICHMAN and OTHER (7 UNITS) | 5t(1)-15t(2) and 20t (4) |

| MULTIPLE JIB CRANES OF VARIOUS MODELS | |

QUALITY GUARANTEE

We can improve your business by providing you with high-quality products, tested and measured to your requested specifications.

Following the best industry benchmarks, we guarantee repeatable welding procedures, tight tolerances, and excellent workmanship by relentlessly working to improve our production processes and investing in the latest technology.

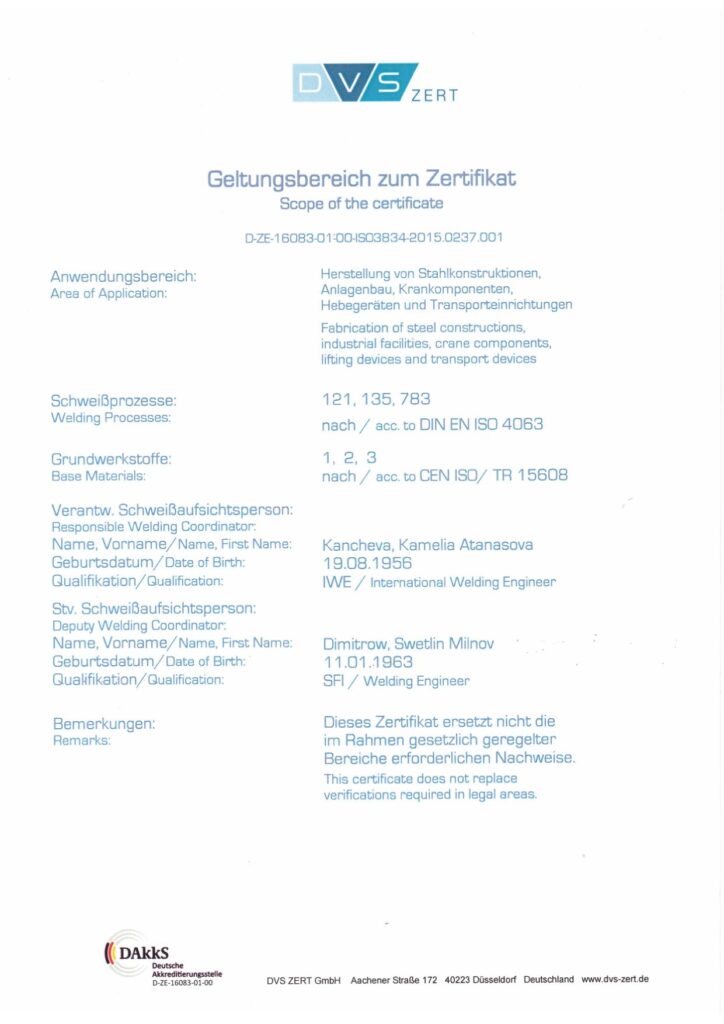

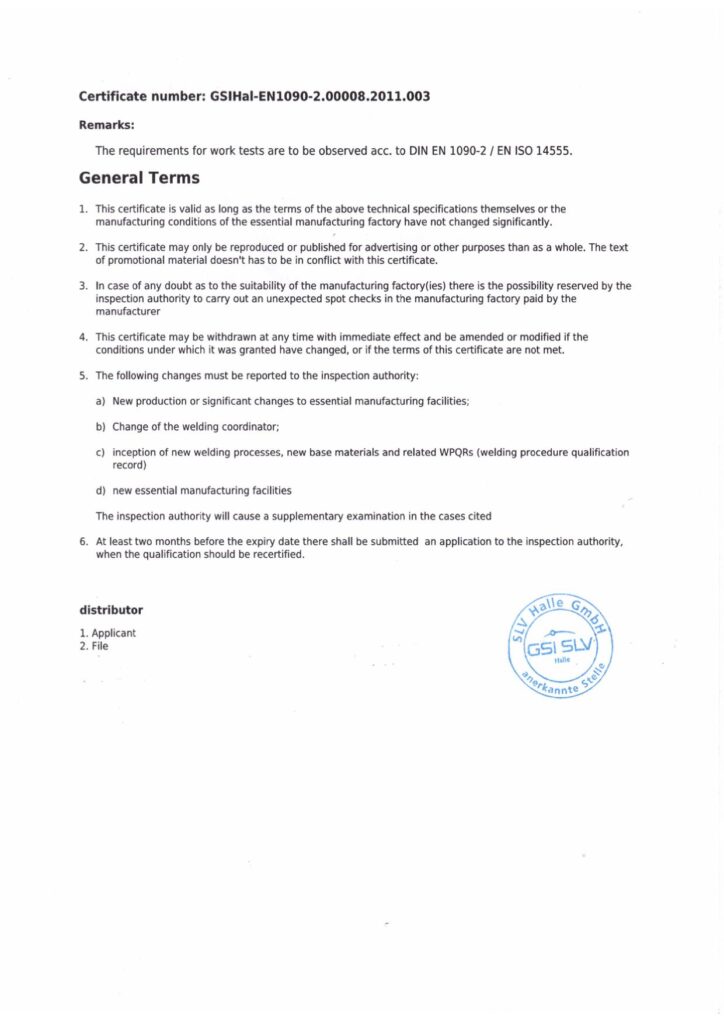

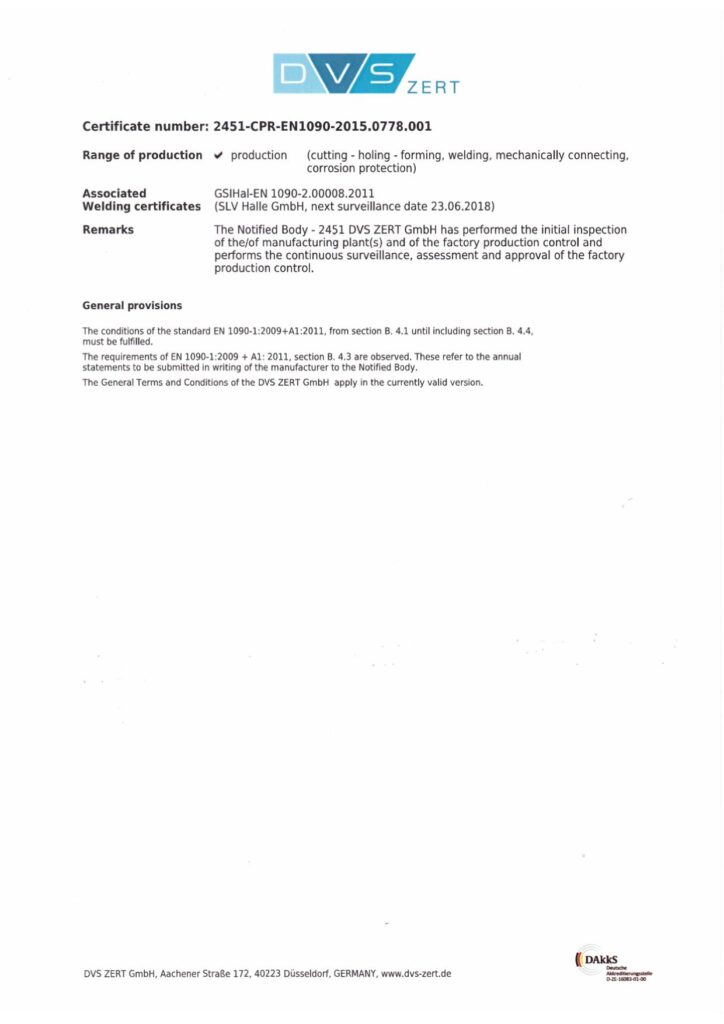

CERTIFICATIONS

Validating Our Commitment to Excellence: Upholding the Highest Quality and Meeting Stringent Industry Standards Through Certifications