As industries worldwide strive for sustainability, metal production and recycling are undergoing significant transformations. The demand for environmentally responsible manufacturing practices is driving innovation in sustainable metal processing, reducing waste, and increasing efficiency. From renewable energy-powered smelting to advanced recycling techniques, the metal industry is embracing sustainable solutions to meet the growing emphasis on circular economy principles.

The Need for Sustainability in Metal Production

Metal production is traditionally resource-intensive, requiring large amounts of energy and raw materials. Mining, smelting, and refining contribute to carbon emissions and environmental degradation. By adopting sustainable practices, manufacturers can reduce their environmental footprint while maintaining productivity and profitability.

Key Trends in Sustainable Metal Production

1. Green Energy in Metal Processing

One of the most significant trends in sustainable metal production is the shift toward renewable energy sources. Companies are increasingly using wind, solar, and hydropower to power smelting and refining operations, significantly reducing carbon emissions. Green hydrogen is also emerging as a cleaner alternative to traditional fossil fuels in metal production.

2. Carbon Capture and Reduction Technologies

Industries are investing in carbon capture and storage (CCS) solutions to minimize greenhouse gas emissions. New technologies are being developed to capture CO₂ generated during metal production and repurpose it for industrial use or store it safely underground.

3. Advanced Recycling and Circular Economy Practices

Recycling plays a crucial role in reducing the demand for virgin metal extraction. Innovations in metal recycling include:

- Automated sorting systems that improve the efficiency of separating different metal types.

- Closed-loop recycling, where manufacturing byproducts are reused in production cycles, minimizing waste.

- Enhanced alloy recovery techniques that extract valuable materials from complex scrap metal sources.

4. Lightweight and High-Performance Alloys

The development of lightweight and high-strength alloys is helping industries reduce material consumption while maintaining durability. These advanced materials improve fuel efficiency in automotive and aerospace applications, contributing to overall sustainability.

5. Eco-Friendly Coating and Surface Treatments

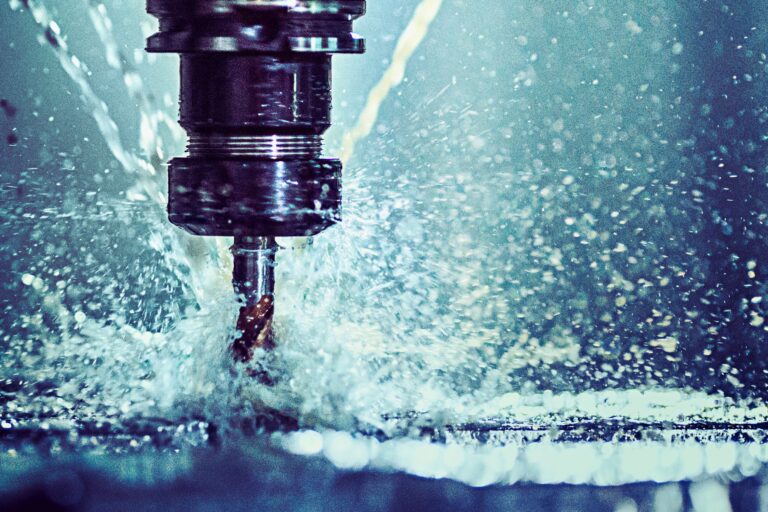

Traditional metal coatings often contain hazardous substances. New environmentally friendly coatings, such as water-based and bio-based treatments, are reducing harmful emissions while maintaining corrosion resistance and durability.

The Role of Digitalization in Sustainable Metal Manufacturing

Digital technologies are driving sustainability efforts by optimizing resource use and reducing waste. Key innovations include:

- AI-powered predictive maintenance, which reduces equipment failures and extends machinery lifespan.

- Real-time data monitoring to track energy consumption and optimize manufacturing processes.

- Blockchain technology to improve transparency in sustainable sourcing and metal recycling.

Challenges and Future Outlook

While sustainable metal production and recycling present many opportunities, challenges remain, including:

- High initial investment costs for adopting greener technologies.

- Regulatory compliance complexities across different regions.

- Material recovery limitations in recycling certain alloys and composites.

Despite these challenges, the future of sustainable metal production is promising. Companies investing in eco-friendly processes and circular economy strategies will not only reduce their environmental impact but also gain a competitive edge in a market increasingly focused on sustainability.

At SL Industries, we understand the importance of sustainable metal production and recycling in shaping the future of manufacturing. By keeping pace with industry innovations and adopting environmentally responsible practices, manufacturers can contribute to a more sustainable and resource-efficient future.