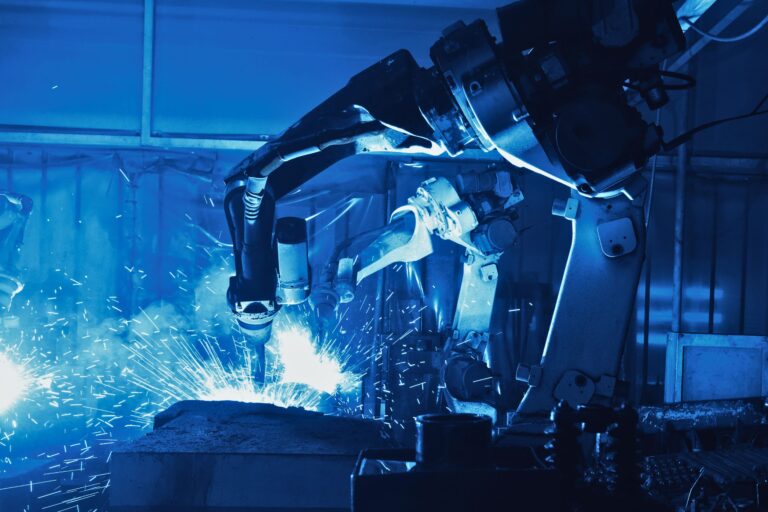

At SL Industries Ltd., precision, efficiency, and innovation form the backbone of our manufacturing processes. One of the most crucial tools in our operations, especially for large-scale and complex projects, is the CNC-controlled large boring and milling machine. These machines represent the pinnacle of modern machining technology, enabling us to deliver high-quality products with unparalleled accuracy and consistency.

The Versatility of CNC Large Boring and Milling Machines

CNC-controlled large boring and milling machines are designed to handle heavy-duty applications, particularly in industries that demand precision and strength, such as construction, mining, and aerospace. These machines are capable of processing large and complex components that require both boring and milling operations. The CNC (Computer Numerical Control) technology allows for precise control over multiple axes, which ensures that each part is machined to the exact specifications required by the client.

Accuracy and Precision on a Grand Scale

The defining feature of CNC-controlled large boring and milling machines is their incredible accuracy, even when working with oversized components. At SL Industries, we regularly work on parts that reach lengths of 10-12 meters, and maintaining precision at this scale is critical. CNC technology enables our machines to maintain tolerances within microns, allowing for the creation of components that fit seamlessly into larger assemblies. This is especially important in industries where even the smallest deviation can cause significant issues in the final product.

Efficiency and Automation

Efficiency is key to modern manufacturing, and CNC-controlled machines excel in this regard. These machines are automated, meaning they can perform complex machining operations with minimal human intervention. Once the initial setup and programming are complete, the CNC system controls the machining process, ensuring consistent quality across large production runs. This level of automation reduces the need for manual adjustments, cutting down on production time and ensuring a quicker turnaround for our clients.

Moreover, CNC machines can multi-task, handling both boring and milling operations within the same setup. This reduces the need to move the component between machines, further increasing efficiency and reducing the risk of errors during transfers. At SL Industries, this integrated approach allows us to meet tight deadlines without compromising on quality.

Capabilities for a Wide Range of Materials

CNC-controlled large boring and milling machines are incredibly versatile when it comes to the materials they can process. Whether it’s high-strength steels, aluminum, or specialized alloys, these machines can handle the demands of heavy-duty machining while maintaining precision. This versatility is vital for serving diverse industries with varying material requirements, from large crane parts in port equipment to structural components in industrial machinery.

Real-World Applications

The capabilities of CNC-controlled large boring and milling machines are evident in the real-world applications we support. From the construction of massive crane arms to the precise components used in heavy-duty excavators, these machines enable us to produce parts that are both large in scale and intricate in design. At SL Industries, we take pride in using this technology to meet the most demanding specifications, ensuring that our clients receive components that perform reliably in even the harshest environments.

Pushing the Boundaries of Manufacturing

As we continue to push the boundaries of what’s possible in metal manufacturing, CNC-controlled large boring and milling machines remain at the core of our operations. Their precision, efficiency, and versatility enable us to meet the evolving demands of industries that rely on high-quality, durable components. At SL Industries, we are committed to leveraging this technology to deliver products that exceed expectations and set new standards for excellence in manufacturing.

Our dedication to innovation ensures that we will continue exploring new ways to maximize the potential of CNC technology, always striving to provide our clients with the best solutions for their needs.