From Paper to Digital: Practical Part Identification Methods for Heavy Fabrication (Tags, Stamping, Marking, QR)

Why part identification is now a production and commercial issue In heavy fabrication, traceability breaks most often at a simple…

Why part identification is now a production and commercial issue In heavy fabrication, traceability breaks most often at a simple…

Why traceability is becoming a commercial requirement In heavy fabrication and welded assemblies, the cost of uncertainty is high. A…

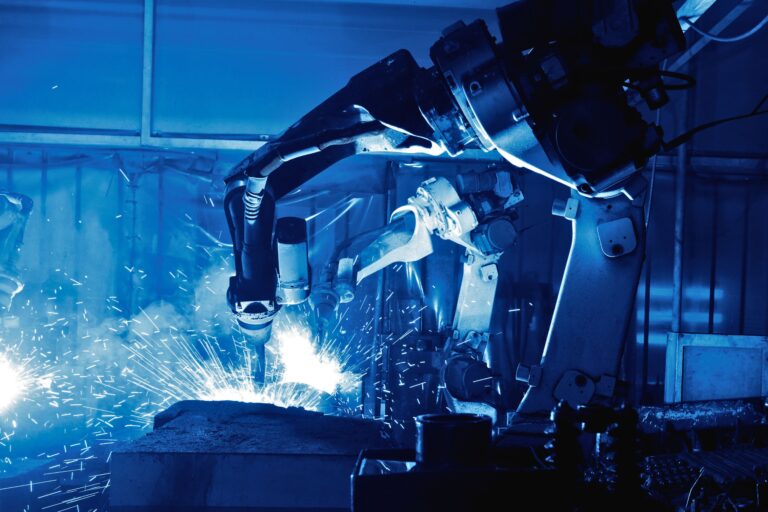

Why heavy weldments expose process weaknesses Heavy weldments are unforgiving because distortion, fit up variation, and heat input effects compound…

Industrial manufacturing starts 2026 with uneven demand signals. In Europe, activity remains under pressure: the HCOB Eurozone Manufacturing PMI ended…

High‑mix manufacturing, tighter tolerances, and faster takt times are pushing visual quality control beyond the limits of manual inspection and…

Customers and regulators increasingly expect transparent, comparable environmental data for metal components. Life Cycle Assessment (LCA) and Environmental Product Declarations…

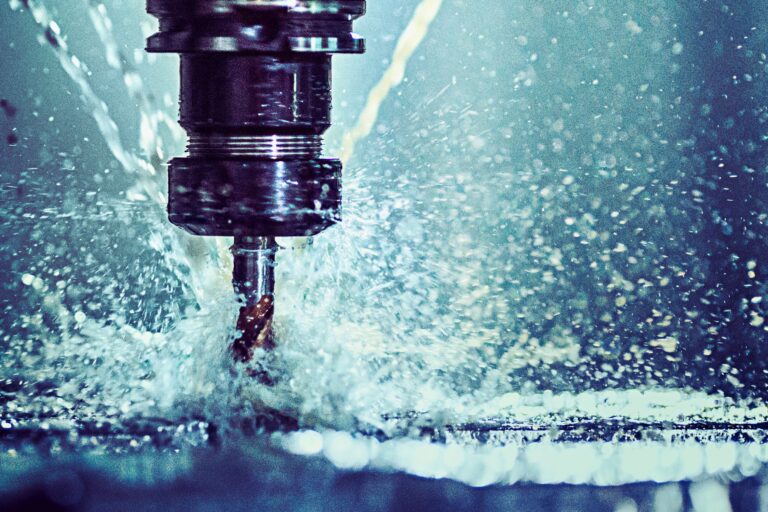

Modern metal components must withstand abrasion, contact fatigue, and cyclic loading—often while holding tight tolerances. Two complementary surface-hardening approaches—vacuum heat…

Competitive manufacturing hinges on the speed and reliability with which lines switch from one product to another. Tooling and fixturing—together…

Manufacturing organizations are accelerating digital transformation to gain real‑time visibility, shorten changeovers, and improve quality. Achieving these outcomes depends on…

Across aerospace, automotive, energy, and precision engineering, manufacturers are under pressure to increase productivity while reducing environmental impact and total…

End of content

End of content

We use cookies on this site to enhance your user experience.

For a complete overview of the cookies used, see our privacy policy.